Stock Take, Physical Inventory, Cycle Counting

inventory

Traditional methods of scanning stock involve lifting staff up to great heights using a forklift.

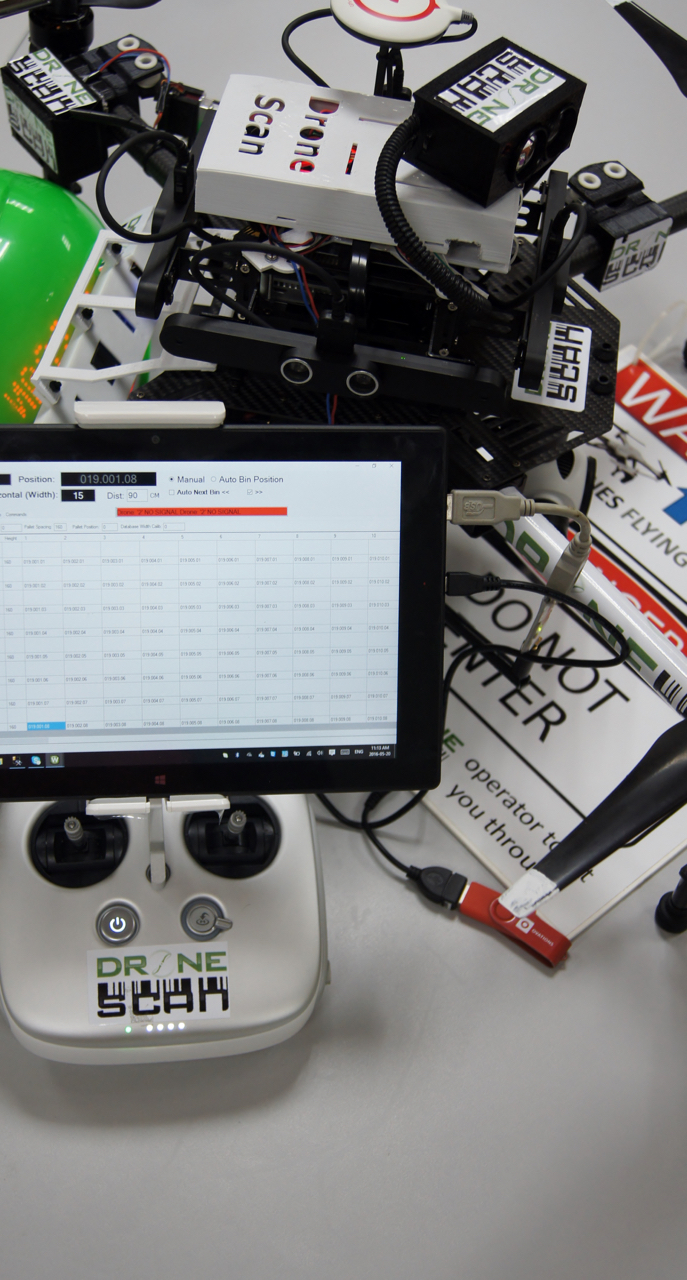

DroneScan has developed three revolutionary robotic systems for data collection in large uniform warehouses. These solutions for inventory stock take, provide live feedback and integration with Warehouse Management systems. They have proven to save hundreds of man-hours but most importantly have provided a safer alternative to traditional labour-intensive methods involving reach trucks, forklifts, man-cages and scissor-lifts.

A live video feed allows the operator to inspect the condition of products or verify the contents of the pallets.

Video and photo images can later be associated to scanned items in the database for off-line viewing.

The simplicity of the DroneScan system means that there are no expensive infrastructure costs needed to setup a warehouse.

The only preparation is to load up a file of the warehouse contents into the DroneScan database. The Hummingbird, Buffalo or Meerkat units set up and run to collect data. And finally, after or during scanning, reports and files can be generated and sent directly to the warehouse manager or uploaded directly into the WMS.

Both the Hummingbird and Buffalo systems are portable allowing one Hummingbird or Buffalo unit to be utilised in different warehouses. The Hummingbird and Buffalo can be setup in 10 minutes and packed away in 5 minutes to be moved to another location. They come with robust travel cases and the Hummingbird system can be transported within airline baggage weight allowances.

Some warehouses have good quality bin location barcodes correctly positioned on the racks. In these cases the Hummingbird and Buffalo can scan the bin location barcodes on the racks and use them to improve the accuracy of the position estimation.

Inspection of stock

Inspecting the condition of items or verifying the contents of a product is usually done manually. DroneScan provides a way to do this quickly and efficiently. As the drones are fitted with a camera, DroneScan allows still images to be taken for later processing or a live video feed for FPV viewing.

The still images and the video footage can be uploaded to the server and linked to the item in the warehouse management software for later retrieval and reporting purposes.

The DroneScan software associates images with scanned items and this can be viewed offline using the DroneScan software or uploaded to the customer's WMS.